Paradigm Change in work Assignment & jobs Redesign reduces production Manpower to half

Excess capacity of synthetic yarn manufacturing, Prevalent in India in mid nineteen nineties severely Impacted in textile mill, employing more than 500 Production worker. Hence cost cutting through Manpower reduction was compulsive need, for Which the company sought Actuate Business Consulting’s Intervention. Consultants from actuate applied Unconventional methods and techniques apart from using Time study, Production study Flowcharting, Multiple activity chart, Work record assess the optimum Analysis & Analytical Estimation Manpower required

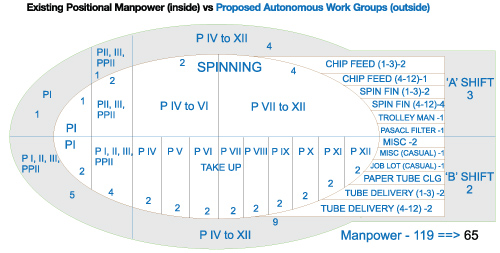

Autonomous work groups were formed for operating cluster of similar machines / processor to benefit from economies of aggregation, in place of deploying Positional Manpower with individual worker(s) assigned for specific Task(s)/ Machines(s).

Jobs were redesigned using job Enrichment, Job Enlargement and Multi-skilling principals with the activities for routine Maintenance, simple quality checks, Materials sorting and Heading & Transportation made integral Part of Operator’s responsibility. It helped established direct & explicit accountability and improved productivity because of lesser interfaces with better motivation & empower workmen.

Number of Men required in each Autonomous Work Group were determiner using Stander time developed through Work measurement studies carried out for individual activities, frequency of occurrence of each activity and likelihood of simultaneous occurrence of activities and concurrent requirement of operators calculator by combinatorial Probability. The numbers so determines, were validated by conducting Activity Sampling studies. Workmen deployed for off-line activities were moved from General Shift to regular shift that helped relieving of workers & Job rotation and unskilled off-line Support activities were sub-contracted on unit output rate basis.

Manpower reduced to almost half with fewer grades and levels with the above paradigm shift.